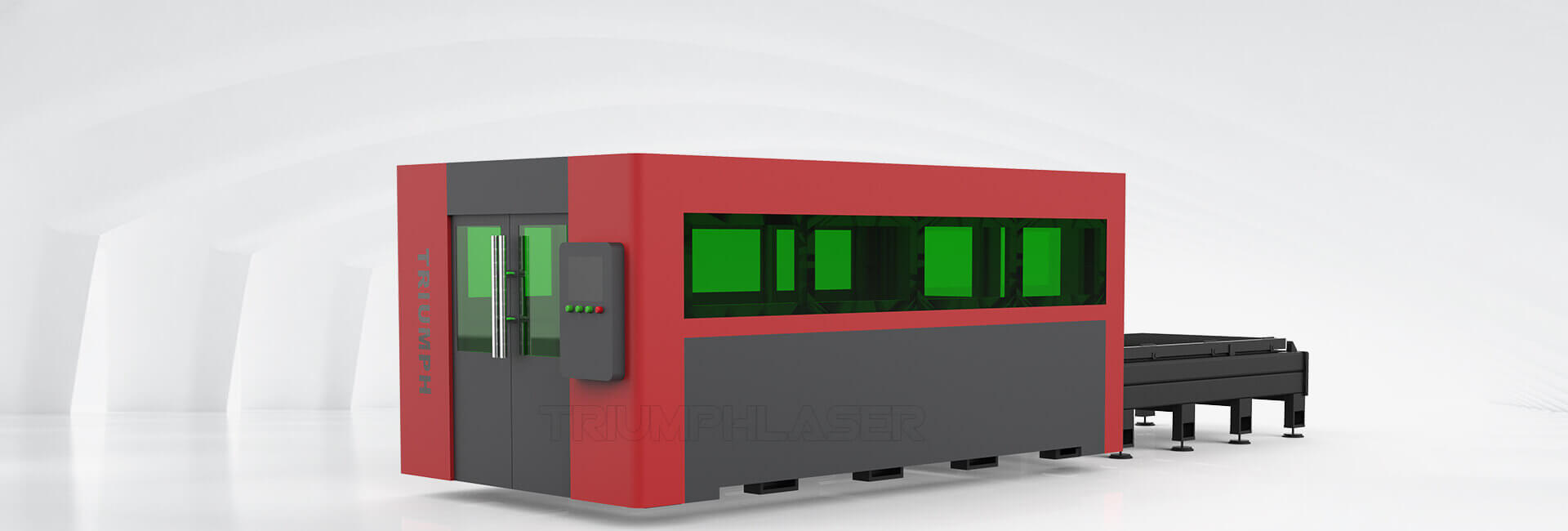

Surrounded Fiber Laser Cutting Machine

The fully sealed design with true laser protection glass added to make the machine safer and more reliable. The two work tables move independently and do not interfere with each other. The design of this independent moving work tables makes it easier to clean the slag.

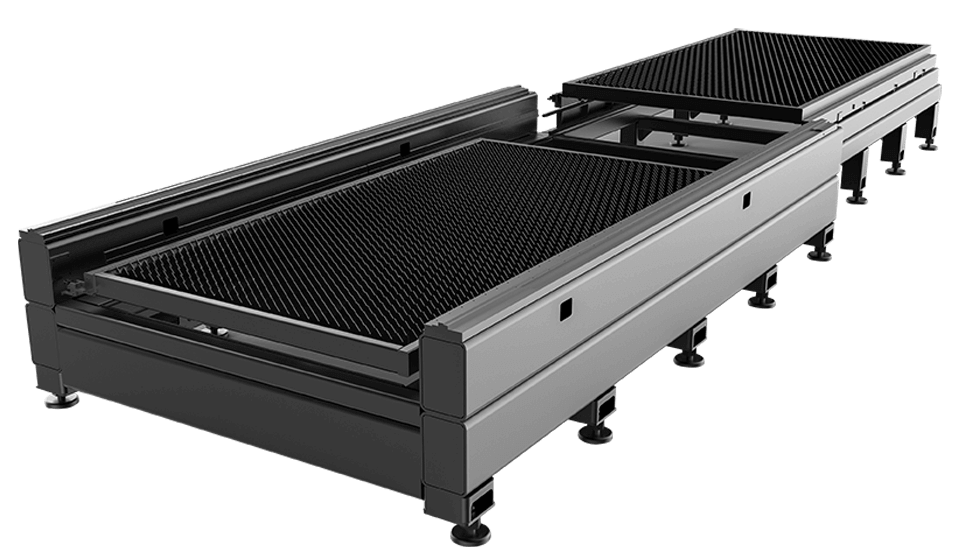

Machine Body

Equipped with a high-low exchange platform, this laser cutting machine operates more efficiency due to the short exchange period of only 15 seconds.

The metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life.

Cast Aluminum Beam

Cast aluminum crossbeam 50% lighter than made by steel

Cast Aluminum Beam made by10-ton steel mould with better rigidity. And the weight is 1/2 lighter than traditional welding iron gantry.

Japan Servo Motors and Drivers

The electric and drive systems provided by Japan YASKAWA offer customers a faster rotation speed and better stability.

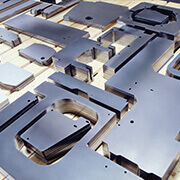

Raytools Laser Head

The laser head made in Swiss is suitable for the medium and small power metal sheet fiber laser cutting machine, with a diversified interface setting so that it can be matched with all kinds of mainstream fiber lasers. The cutting head adopts the optimization of optical design, light weight, small volume, easy to use, with a height sensor can make cutting more efficient, but low price,which is preferred for cutting equipments with laser power 500w or lower.

Auto – focus:Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Accuracy:Increasing perforation focus length, separately setting perforation focal length and cutting focal length, enhance cutting accuracy.

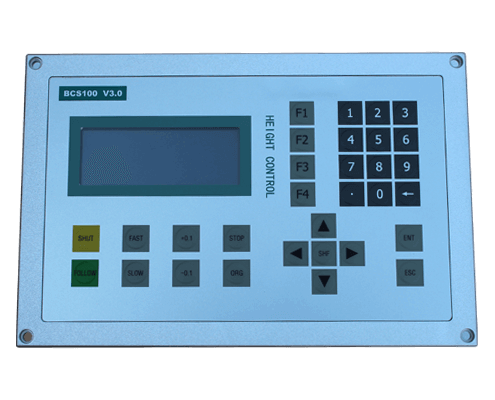

High Efficiency Operating System

The operating system can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhancing the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

Technical Parameters

| Model | TR-F1325/TR-F1530 |

| Working Area | 1300*2500mm / 1500*3000mm |

| laser wavelength | 1077nm-1083nm |

| Laser Power | 500W-4000W |

| Cooling Type | Water cooling |

| Cutting Thickness | Depending on materials |

| Position Type | Red Dot |

| Operation Mode | CW |

| Power Tuning Range | 10%-100% |

| Max Modulation Freq | 50KHz |

| Max Power Consumption | 2500W |